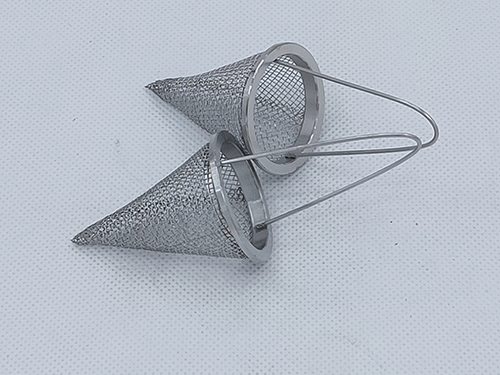

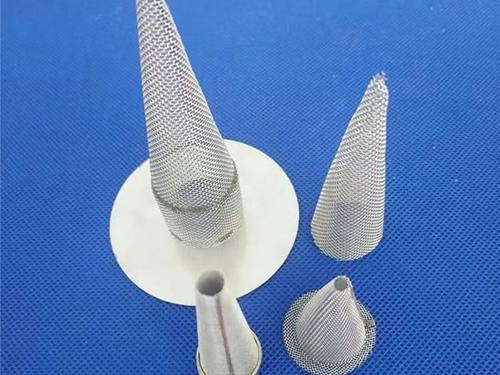

Conical filters, also known as temporary filters, as the name suggests, have a vertebral shape and belong to the pipeline coarse filtration series. Its form is simple, and removing impurities from the medium inside the pipeline ensures the normal operation and stability of the equipment, achieving a stable process and ensuring safe production of the equipment.

Function:

(1) Oil suction filter: This filter is located on the suction pipeline of the pump, filtering out residual pollutants in the oil tank that enter through the air hole, and has the function of protecting the pump. However, in order to avoid cavitation in the pump, it is necessary to pay sufficient attention to pressure loss, and generally use 100-200 mesh coarse metal mesh or notched metal wire material. Therefore, it is not a filter that controls the pollution concentration of the system.

(2) High pressure pipeline filter (A): Located on the outlet pipeline of the pump, it has the function of protecting pollutants from entering the system. Therefore, the concentration of pollutants in the system can be controlled. However, as it is a high-pressure main pipeline, it is subject to pump pulsation and pressure impact, so the material and strength of the filter elements should be carefully considered.

(3) High pressure pipeline filter (B): In the system, this filter, also known as terminal filter, is installed to protect hydraulic components that are particularly sensitive to pollution. Therefore, it often has a smaller filtration particle size than other filters. Therefore, it is necessary to choose a larger capacity when using. In addition, the material and strength of the components should also be fully considered, just like (A).

(4) Return filter: located on the return oil pipeline of the system, its function is to capture pollutants generated or invaded in the system before returning to the oil tank. Therefore, it is the most effective and important filter for controlling the concentration of system pollution. Although it is a low-pressure pipeline, pulsation or pressure impact may occur depending on the operating condition of the transmission device, so the material and strength of the components should be fully considered. Imported pump

(5) Circulation filter: located on the return oil path of the fuel tank circulation, the system has a large capacity, so it is often used when strict cleanliness requirements are required. Even if the system is not working, it can capture pollutants in the fuel tank. Therefore, the efficiency of reducing pollution concentration is the best. Additionally, a cooler is installed, which has the advantages of simultaneous cooling and easy maintenance. But it requires specialized pumps and motors, which is expensive.

(6) Air filter: installed on the fuel tank to prevent pollutants from mixing with air due to changes in the oil volume of the tank. Therefore, the filtration accuracy should have the same or higher performance as the filter, and there should be sufficient room for capacity to prevent pump cavitation caused by negative pressure in the oil tank due to hole blockage. Pay special attention when the surrounding environment is harsh.